Cotton Color Grading and Classification

Cotton color grading is a system used to classify the color of cotton fibers based on their appearance. The color of cotton can vary due to factors such as maturity, cleanliness, and processing techniques. The most commonly used color grading system for cotton is the HVI (High Volume Instrument) color grading system, which provides objective and consistent measurements.

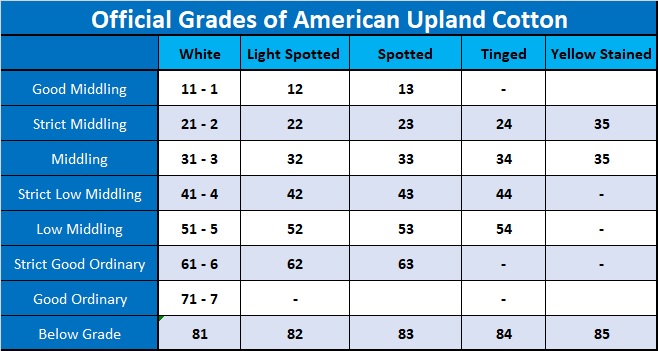

The HVI color grading system assigns a color grade to cotton fibers based on three primary attributes: color, trash, and extraneous matter. These attribute is graded on a scale from 1 to 8, with 1 being the best and 8 being the poorest. Here are the details of the color grades and their descriptions:

The smaller the numerical value, the higher the quality; for instance, a grade of 31-3 surpasses the base grade of 41-4, indicating superior excellence. Higher numbers (such as 42 or 52) signify a lackluster hue. Usually attributable to weathering towards the end of the season. Diminished color intensity hampers the dye absorption capabilities of the fibers and detrimentally impacts spinning efficiencies.

Leaf content grading in cotton refers to the evaluation and classification of the amount of leaf matter present in a sample of cotton fibers. Leaf content is an important quality parameter. The excessive leaf matter can negatively impact the processing and spinning of cotton fibers.

The High Volume Instrument (HVI) is a widely used technology for measuring various parameters of cotton fibers. Here are the key parameters that the HVI measures and their corresponding descriptions:

Key Parameters Measured by the HVI for Assessing Cotton Quality and Suitability

- Length: The HVI measures the average length of cotton fibers in millimeters (mm). Fiber length is an important quality parameter, as longer fibers generally have better spinning properties and produce stronger and more uniform yarns.

- Length Uniformity: This parameter, expressed as a percentage, represents the uniformity of fiber lengths within a cotton sample. Higher length uniformity indicates a more consistent fiber length distribution, leading to improved spinning efficiency and yarn quality.

- Strength: The HVI measures the strength of cotton fibers in grams per tex (g/tex) or centinewtons per tex (cN/tex). Fiber strength is a crucial characteristic that determines the durability and performance of spun yarns and fabrics.

- Micronaire: Micronaire is a measurement of the fineness or thickness of cotton fibers. Micronaire values help assess the suitability of cotton for specific textile applications, with lower values indicating finer and more desirable fibers.

- Color: The HVI assigns a color grade to cotton fibers, as discussed in the previous response. The color grading system provides information about the visual appearance and cleanliness of cotton fibers, aiding in assessing their aesthetic appeal and market value.

- Trash: The HVI measures the amount of non-fiber impurities, often referred to as trash, present in a cotton sample. Lower trash content is desirable as it minimizes processing difficulties and improves fiber quality.

- Moisture: The HVI measures the moisture content of cotton fibers as a percentage.

These parameters measured by the HVI provide valuable information about the quality. Processing characteristics, and suitability of cotton fibers for different applications in the textile industry. They enable producers, buyers, and processors to make informed decisions regarding fiber selection, blending, and processing techniques.