Textile Calculations and formulation

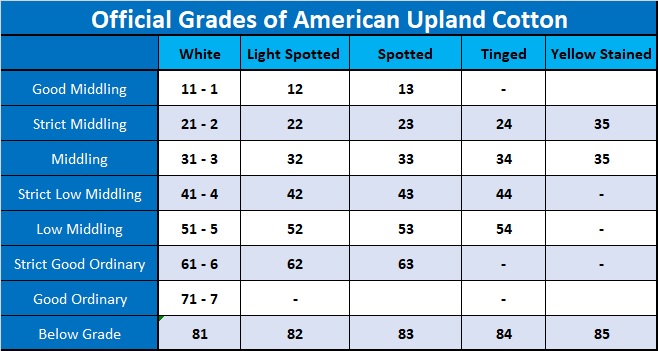

Cotton Color Grades Chart

For complete introduction of Color Grade system Please Click Here

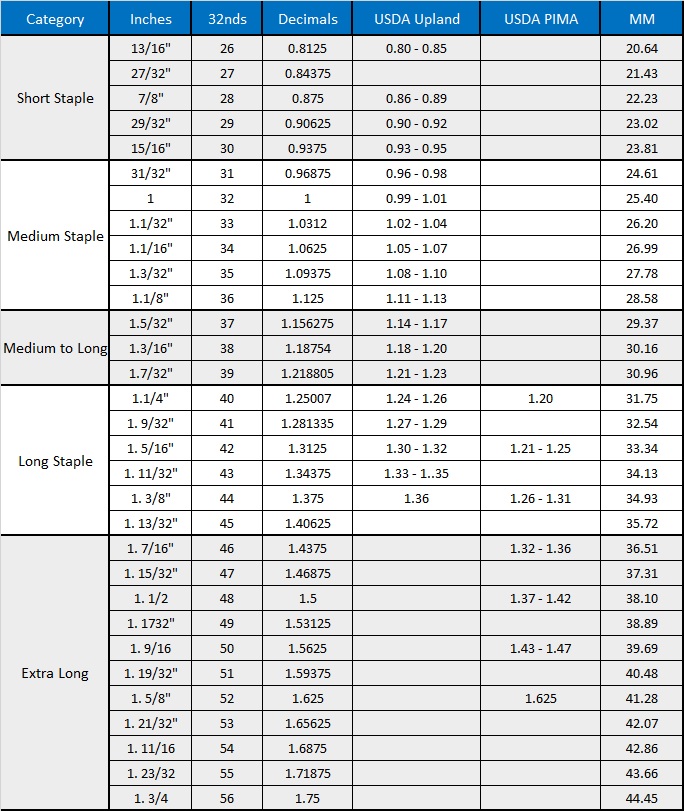

Cotton Staple Length Conversion Chart

Textile Calculations and formulation

Textile Calculations and formulation

Delve into a treasure trove of textile calculations and formulations on our online platform, meticulously assembled to address your diverse needs. Our collection covers a spectrum of essential calculations crucial in the textile industry. Whether you seek fabric yield assessments, precise thread count computations, shrinkage percentages for accurate production planning, or dye ratios for vibrant coloration, our repository caters to every aspect of textile calculation. Each formula is thoughtfully curated to ensure precision and reliability, empowering professionals to streamline their processes and achieve optimal results.

Precision for Efficient Production

Our platform isn’t just a compilation of formulas; it’s a gateway to precision. Accuracy is the cornerstone of efficient production, and our meticulously crafted formulas serve as indispensable tools in achieving this goal. By utilizing our resources, textile experts and manufacturers can elevate their precision in measurements, allowing for meticulous planning and execution in production processes. Accurate calculations minimize waste, optimize material usage, and streamline workflows, contributing significantly to enhanced productivity and cost efficiency in textile manufacturing.

User-Friendly Interface for Enhanced Expertise

Navigating through complex calculations has never been simpler. Our user-friendly interface offers intuitive access to a wealth of textile calculations, ensuring that even intricate formulations are easily comprehensible. Designed for convenience and efficiency, our platform allows textile professionals to effortlessly access and apply these essential calculations in their day-to-day operations. Embrace the power of precision with ease as you explore our platform, empowering yourself with the tools needed to excel in the dynamic textile industry.

For better understanding about Cotton fiber staple length Click Here

FAQ

In yarn and fabric production, various calculations are essential for determining quantities, costs, and specifications. Here are some common textile calculations:

Yarn Calculations:

- Yarn Count Calculation:

- Denier or Tex: Measures yarn fineness. Denier refers to the weight in grams of 9,000 meters of yarn, while Tex measures the weight in grams of 1,000 meters of yarn.

- Yarn Length Calculation:

- Yarn Length on a Cone: Calculating the length of yarn wound on a cone or spool based on the number of wraps and the circumference of the cone.

- Yarn Consumption Calculation:

- Yarn Consumption for Weaving/Knitting: Estimating the amount of yarn needed for a specific fabric based on fabric type, density, and dimensions.

- Twist Calculation:

- Twists per Inch (TPI) or Twists per Meter (TPM): Measuring the number of twists in a yarn over a specific length, impacting yarn strength and appearance.

Fabric Calculations:

- Fabric GSM (Grams per Square Meter):

- Calculating the weight of fabric per square meter, crucial for determining fabric density and thickness.

- Fabric Consumption Calculation:

- Estimating the amount of fabric needed for a garment or project based on the fabric width, design, and dimensions.

- Fabric Yield Calculation:

- Determining the efficiency of fabric usage during cutting and production, considering wastage and usable fabric area.

- Shrinkage Calculation:

- Estimating the amount of shrinkage in fabric after washing or processing, vital for pre-shrinking considerations in garment production.

- Dyeing and Chemicals Calculation:

- Calculating the amount of dye or chemicals required for dyeing or finishing fabric, ensuring consistency and color accuracy.

- Cost per Meter/Yard Calculation:

- Determining the cost of fabric per unit length, considering raw material costs, processing expenses, and overheads.

- Pattern Repeats Calculation:

- Planning and aligning fabric patterns in printing or weaving by calculating the length of repeats needed to match designs.

These calculations aid in various stages of yarn and fabric production, from determining yarn specifications to optimizing fabric usage, ensuring quality, and managing costs efficiently.

Textile Calculations:

What are textile calculations?

Textile calculations involve various mathematical computations used in the textile industry to determine fabric requirements, cost estimations, sizing, and other crucial aspects of textile production.

What are some common textile calculations used in the industry?

- Fabric Consumption: Calculating the amount of fabric required for a specific garment or project based on its design, dimensions, and fabric width.

- Cost Estimations: Determining production costs considering raw materials, labor, overheads, and other expenses.

- Sizing and Grading: Computing pattern sizes and proportions for different garment sizes.

- Yield Calculations: Measuring the efficiency of fabric usage and waste during cutting and production processes.

How is fabric consumption calculated for a garment?

Fabric consumption is often calculated by multiplying the dimensions of pattern pieces by the quantity needed and then accounting for fabric width, seam allowances, and any pattern matching requirements.

What factors affect fabric consumption calculations?

- Design Complexity: Intricate designs or patterns may increase fabric consumption.

- Fabric Width and Type: Different fabric widths and types affect the amount needed.

- Garment Size: Larger sizes may require more fabric compared to smaller sizes.

- Pattern Repeats: Patterns that need matching or alignment may increase fabric requirements.

How are cost estimations computed in the textile industry?

Cost estimations involve calculating raw material costs, labor expenses, overheads, and additional expenses incurred during production. This helps in determining the total cost per unit or per project.

What is sizing and grading in the context of textile calculations?

- Sizing: Involves creating patterns for different garment sizes while maintaining proportions and fit.

- Grading: The process of adjusting patterns between sizes while preserving the original design and fit, often through a set of size increments or decrements.

How are yield calculations used in textile manufacturing?

Yield calculations assess the efficiency of fabric usage during cutting and production. It helps minimize wastage and optimize fabric usage, ultimately reducing costs and maximizing output.

Are there software tools available for textile calculations?

Yes, various software and applications are available that streamline and automate textile calculations for fabric consumption, costing, pattern making, and production planning, enhancing accuracy and efficiency.

How important are accurate textile calculations in the industry?

Accurate textile calculations are crucial for efficient production planning, cost control, inventory management, and ensuring quality and consistency in textile products.

Can textile calculations vary based on different production methods or materials used?

Yes, textile calculations can vary depending on production techniques (e.g., woven vs. knitted fabric) and materials used (e.g., natural vs. synthetic fibers), requiring specific formulas or considerations for accurate estimations.

These FAQs offer insights into the importance, methods, and considerations of textile calculations used in various aspects of the textile industry, aiding in efficient production planning and cost management.

If you are looking for daily cotton and yarn price updates please Click Here