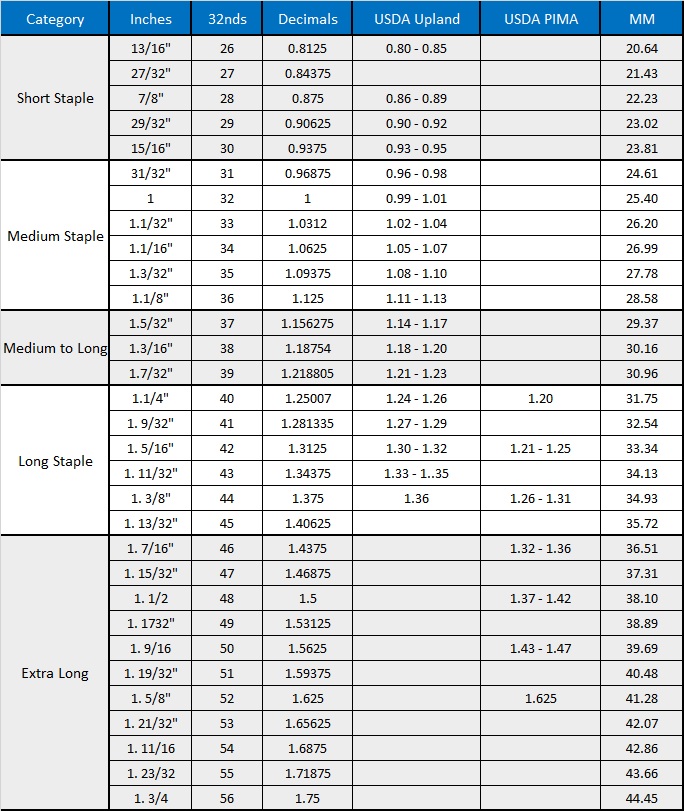

Cotton Staple Length Conversion Chart

Cotton Staple Length Conversion Chart

Staple length in cotton refers to the length of the individual fibers or strands of cotton lint. It is measured in inches, and it is an essential characteristic used to assess the quality and value of cotton fibers. The staple length can vary from very short to very long, depending on the cotton variety and growing conditions.

Staple length is crucial in the textile industry as it directly affects the quality and performance of cotton fibers during spinning, weaving, and other manufacturing processes. Here are some key aspects of staple length and its importance:

How Staple Length Shapes Cotton’s Strength, Quality, and Market Value

- Fiber Strength: Longer staple fibers tend to have higher tensile strength, meaning they can withstand more stress and strain without breaking. This strength is important during the spinning process to produce strong and durable yarn.

- Spinning Efficiency: Longer staple fibers align more easily during spinning, leading to smoother and more even yarn production. This results in improved spinning efficiency, reduced yarn breakage, and better yarn quality.

- Yarn Strength and Fineness: Longer staple lengths contribute to the production of finer and stronger yarns. They provide more contact points between the fibers, resulting in better cohesion and increased yarn strength.

- Fabric Quality: The staple length affects the appearance, feel, and performance of the fabric. Longer staple fibers produce fabrics with reduced pilling, better color retention, improved luster, and a softer hand feel.

- Processability: Cotton fibers with uniform staple lengths are easier to process in spinning mills. They require fewer adjustments in machinery settings, leading to smoother operations, higher productivity, and reduced downtime.

- Market Value: Staple length is one of the factors that determine the market value of cotton. Longer staple lengths are generally associated with higher-quality cotton, commanding premium prices in the market.

- It’s important to note that different industries and applications require specific staple lengths. For instance, longer staple cotton is often preferred in the production of high-quality textiles, while shorter staple cotton may be suitable for coarser yarns or non-textile applications like cotton balls or cotton pads.

- Cotton breeders, researchers, and industry organizations like the USDA closely monitor and evaluate staple length to develop and maintain cotton varieties with desired fiber properties. This helps ensure that the cotton produced meets the requirements of various end-use applications and supports the overall sustainability and profitability of the cotton industry.