Yarn Uster Report Description

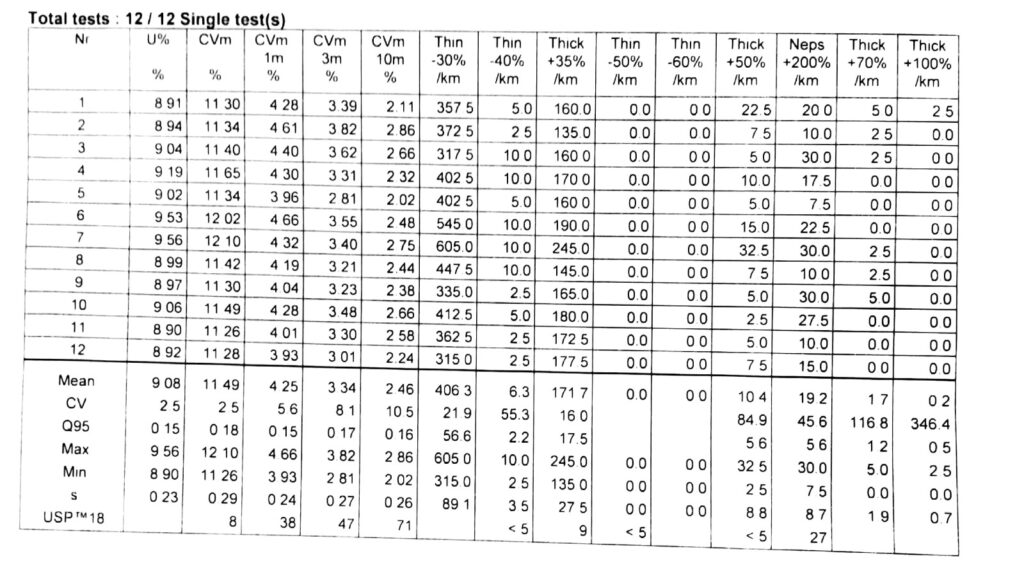

Uster yarn testing parameters are used to test the uniformity in yarn with the help of a highly complex testing machine that has the capability to determine the variation in yarn even less than one denier. It is important to note that Uster Quality Factor (UQF) is not a single number but an umbrella term for all those factors which affect uniformity and other imperfection parameters from raw material till finished product. It also includes skill of machine operators as well as other factors like temperature and humidity conditions etc., whose effect on uniformity cannot be ignored during testing process.

What is U% in Uster Results

Uster Quality Factor (%) is the test of the uniformity in yarn with the help of a highly complex testing machine that has the capability to determine the variation in yarn even less than one denier. It is the test of the uniformity in yarn with the help of a highly complex testing machine that has the capability to determine the variation in yarn even less than one denier. The Uster Quality Factor evaluates the tensile strength and elongation of a sample at its breaking point. The Uster Quality Factor for each sample is calculated by dividing the sample’s weight by its diameter, multiplying this result by 100%, and then dividing by 1,000 (1% = 0.01) to obtain the final Uster Quality Factor.

Thin Places in Yarn

The thin place is the proportion of thin places on yarn and it is expressed as a percentage. In this section, we will discuss the thin place. The thin place is the proportion of thin places on yarn and it is expressed as a percentage. The “thin” place refers to areas in which there are no defects but just interspersed knots or strings that do not form loops. One or two passes with a carded comb can remove a significant percentage of these defects in those areas. However, if various types of defects, like broken threads, are abundant, additional passes might be necessary.

Thick Places in Uster Report of Yarn

The thick place represents the percentage of thick areas on the yarn. One of the methods used to measure yarn thickness is the thickness at break (TBT), which involves repeatedly breaking tweezers into two pieces to determine how many breaks occur before reaching their breaking point. If a tweezer breaks more times than specified, then that means there are more than 3/8″ (1 cm) per meter.

Definition of Neps+200 in Yarn:

The number of neps+200 is the count of knots bigger than 200 micron which are present on every linear meter of yarn. The neps+200 is the count of knots bigger than 200 micron which are present on every linear meter of yarn. Uster Tester 3 and Tester 5 machines determine this value, expressed as a percentage. The Neps+200 value helps assess yarn quality for its potential use as a warp material in the sewing phase of production.

Description of Hairiness in Yarn Results

Uster Hairiness Test Measures number of extra fibers sticking outside from yarn surface per meter length. The hairiness test is a measure of the number of extra fibers sticking outside from yarn surface per meter length. The hairiness test measures yarn by applying pressure to the sample and gauging its swelling response under this pressure. The higher the number, the more likely that your yarn will be suitable for knitting or weaving with natural fiber materials such as wool, silk and cotton as well as synthetic ones such as nylon or polyester.

What is U CV% in Yarn (Complete Definition)

Short name for Uster CV% which stands for coefficient variation produced by Uster Tester 3 and Tester 5 machines. It is the overall measure for all those parameters which affect uniformity and other imperfection parameters. The Uster CV% is the overall measure for all those parameters which affect uniformity and other imperfection parameters.

CV% = U% + tp% + th% + neps+200 + sh% + cvm%.

IPI or Imperfections in Yarn Results

In Normal spun yarns IPI is the total of Thin(-50%)+Thick(+50%) and Neps(+200%)

Description of SH% in Yarn

Short name for Shaft Holes, a defect produced by spinning machine due to rubbing between two components at high speed. It results in reduction in strength as well as leads to produce weak parts in yarn which can break anytime during post-spinning operations. Rubbing two components at high speed causes shaft holes. It results in reduction in strength as well as leads to produce weak parts in yarn. It can break anytime during post-spinning operations.

Definition and description of Yarn Strength

Strength stands for how strong a material is i.e, its resistance against breaking or tearing apart under tension or pressure. Strength is the measure of how strong a material is. The measurement, in grams per denier (g/d), determines yarn strength for specific applications and materials. Tensile strength indicates the amount of force a material can withstand before breaking. Thus, higher values indicate greater strength.

Uster yarn testing parameters are important in assessing the quality of a yarn.

FAQs About Uster Report

Absolutely! The Uster Report is a comprehensive analysis within the textile industry, specifically focusing on yarn quality. Here are some frequently asked questions regarding the Yarn Uster Report:

What is the Yarn Uster Report?

The Yarn Uster Report is a detailed assessment and analysis of yarn quality produced by textile spinning mills. It provides critical data and insights into various yarn parameters, such as evenness, hairiness, imperfections, and strength.

What does the Uster Report measure?

It measures several key parameters of yarn quality, including yarn count, evenness (variation in thickness), imperfections (like neps, thick places, and thin places), hairiness (fiber protrusion), strength, elongation, and more.

Why is the Uster Report important?

The report is crucial for both textile mills and downstream users (like fabric manufacturers) as it helps in ensuring consistent and high-quality yarn production. It allows mills to identify areas for improvement and maintain quality standards, thereby enhancing their competitiveness in the market.

How is the Uster Report used?

Textile mills use Uster testing equipment to evaluate their yarn quality. The data collected is then compiled into a detailed report by Uster Technologies, providing insights and benchmarks against industry standards. Mills can use this information to optimize their production processes and enhance yarn quality.

What benefits does the Uster Report offer?

- Quality Control: It helps mills maintain consistent and high-quality yarn production.

- Process Optimization: Insights from the report enable mills to optimize their spinning processes.

- Benchmarking: Provides a benchmark against industry standards, allowing mills to compare their performance.

- Customer Assurance: It assures downstream customers (fabric manufacturers) of the yarn’s quality, fostering trust and reliability in the supply chain.

How often is the Uster Report generated?

The frequency of generating the Uster Report varies based on the production volume and requirements of the spinning mill. It could be daily, weekly, monthly, or at other intervals as deemed necessary for quality monitoring and improvement.

Who uses the Uster Report?

Primarily, spinning mills, yarn manufacturers, and textile companies utilize the Uster Report to monitor and enhance yarn quality. Additionally, downstream users like fabric manufacturers may also refer to these reports to ensure they’re using high-quality yarn for their production.

Is the Uster Report standardized across the textile industry?

Yes, Uster provides standardized testing methods and parameters that are widely accepted in the textile industry, ensuring consistency and comparability across different mills and regions.

The Uster Report is a pivotal tool in the textile industry, offering essential insights for maintaining and improving yarn quality, thereby impacting the overall quality of textile products.